Building Your Embedded Lab - My Recommendations for Instruments, Tools

Embedded engineers bridge the gap between hardware and software. That means we need tools beyond our editor, compiler, and debugger. Oscilloscopes, multimeters, logic analyzers, hardware debuggers, and on and on. Here are my recommendations for the tools you can use to make embedded development easier!

Note: All Amazon links in this post give me a kickback!

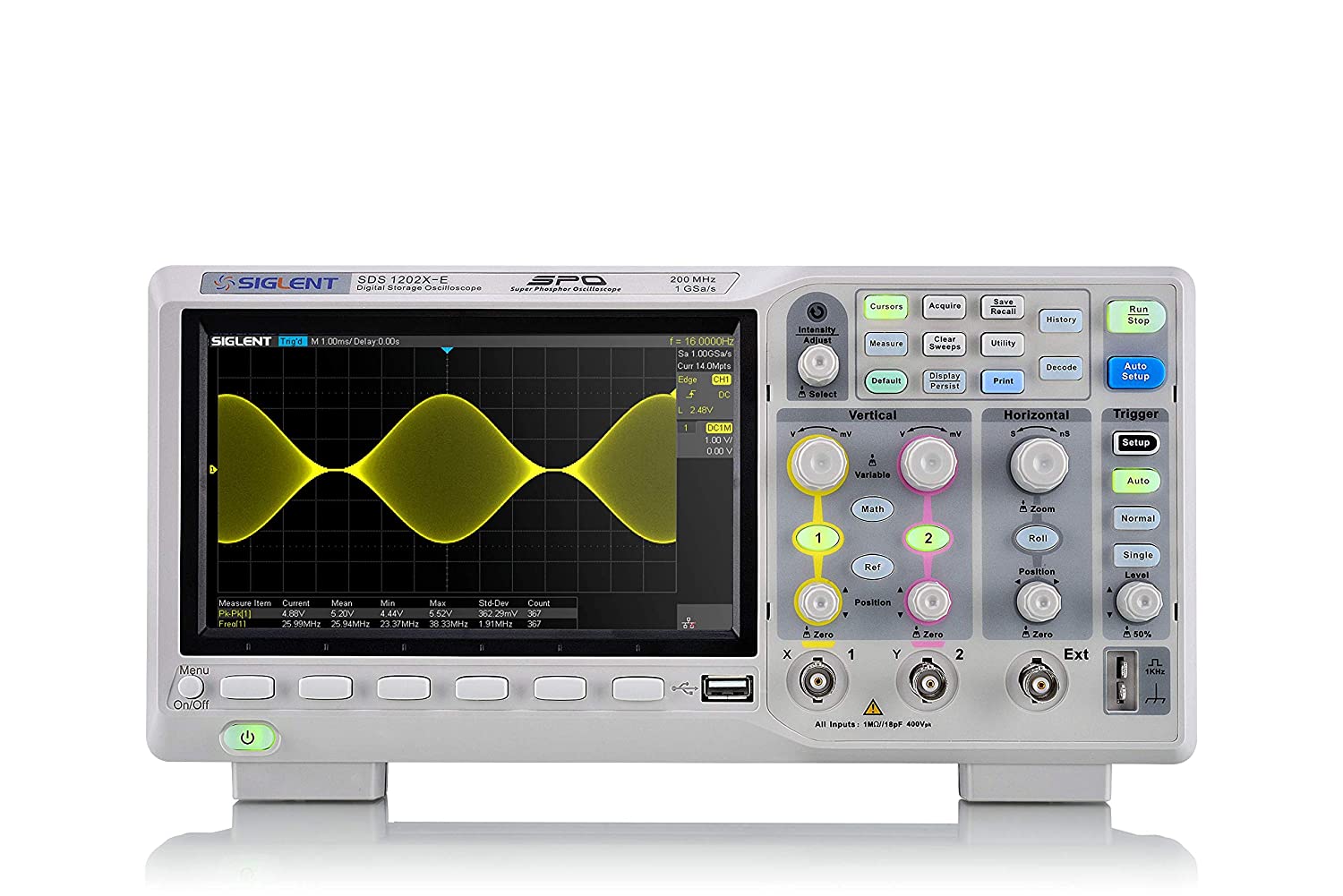

Oscilloscope

Start with the basics! Hopefully you aren't doing anything too strenuous with this oscilloscope. Outside of some power supply evaluation, your best friend should be your logic analyzer. So let's keep it simple. Use something like the following:

This should cover most of your usecases.

Logic Analyzer

Saleae is the be-all, end-all of logic analyzers. There are cheaper clones that exist but the real power of this LA is in its software package and the ease with which custom plugins can be developed. Buy once cry once! There are a number of options within the Saleae family but for many users (with low speed communication buses) their lower tier devices are just fine.

Multimeter

An embedded engineer's multimeter is nowhere near as critical as an electrician's! I mostly use my multimeter for quick voltage measurements or, more often, to verify continuity of new PCBs. Anything will work--I personally use the EEVblog BM786 because it comes with excellent quality probes and supports Dave.

Hardware Debugger

The Black Magic Debug Probe is a game changer for the beginner. printf()s can only get you so far after a while. Using a hardware debugger allows you to step through your program one line at a time (just like a regular, plebian software developer!). It presents a GDB server to the user, connects via USB-C, and supports pretty much every debugging protocol you could desire (including RTT or real-time transfer). I'm a sucker for open source projects so be sure to purchase directly from 1BitSquared to continue supporting the Black Magic project!

Power Supply

Unless you have very exacting requirements, DC power supplies should almost be treated as consumables. Grab the cheapest one you can with constant current so that you can more effectively smoke test boards.

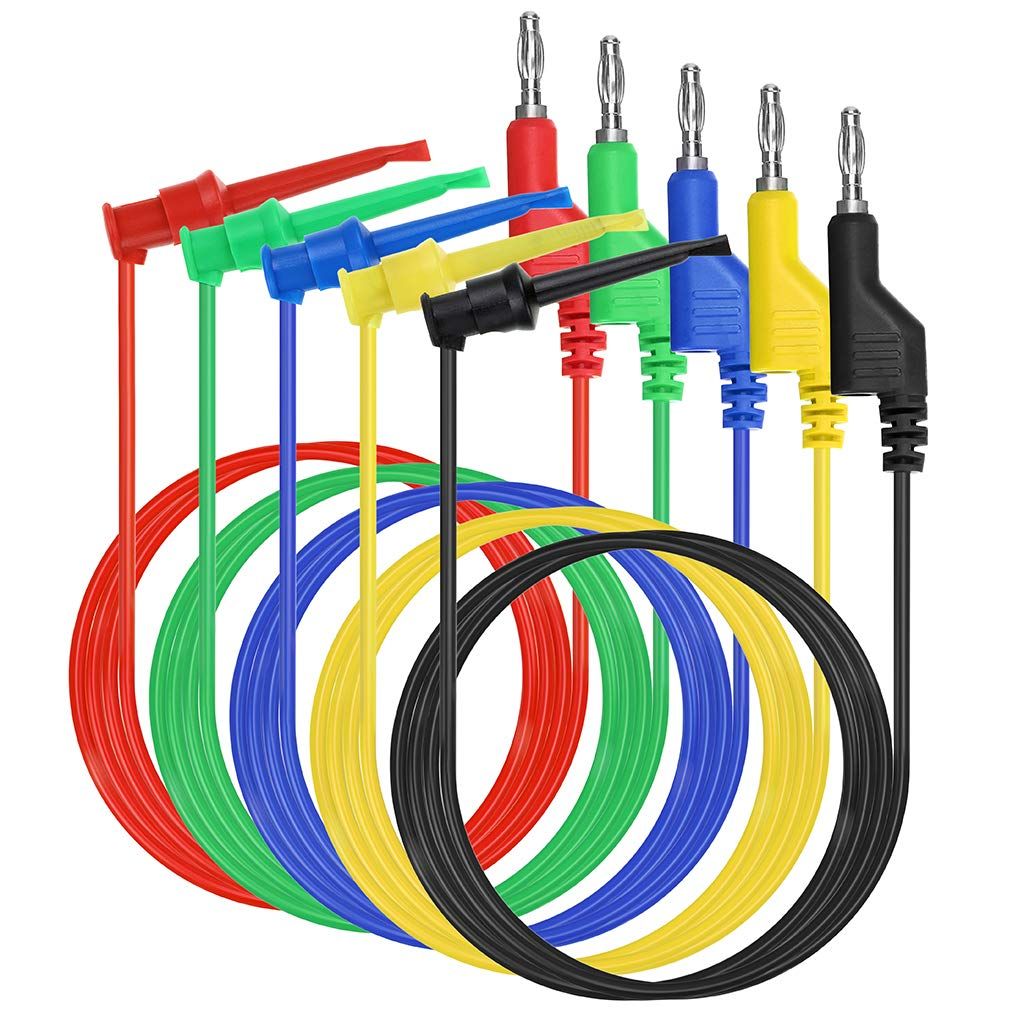

Probes/Leads

Just buy dozens of these. Truly consumable parts. I would recommend getting some with the little hooks and some with dupont connectors.

Board Probing/Fixturing System

PCBite is a game changer for board fixturing and probing. The probes are actually sharp pogo pins (that will cut through flux) and have an excellent weight to them. When you place them on a pad, test-point, or lead they stay there. The board fixtures themselves are also excellent--they are insulated and have strong magnets in their bases to keep things nice and steady. I would recommend picking up a kit with an oscilloscope BNC connector probe included.

Hand Tools

Pick up a pair of flush cutters ASAP if you don't have them already! They may be called flush cutters, but they are the greatest multitool of all time. Tweezers, pliers, cutters--they fixed my marriage. Get the Hakko ones--they have the nicest jaws.

Wire strippers will come in handy eventually. Ben Eater showed off these in one of his breadboarding videos and they are what I have used since then.

An exacto knife is your best friend on a prototype board spin. When you inevitably swap TX/RX lines, use this little guy to scrape off solder mask and bodge together a temporary fix.

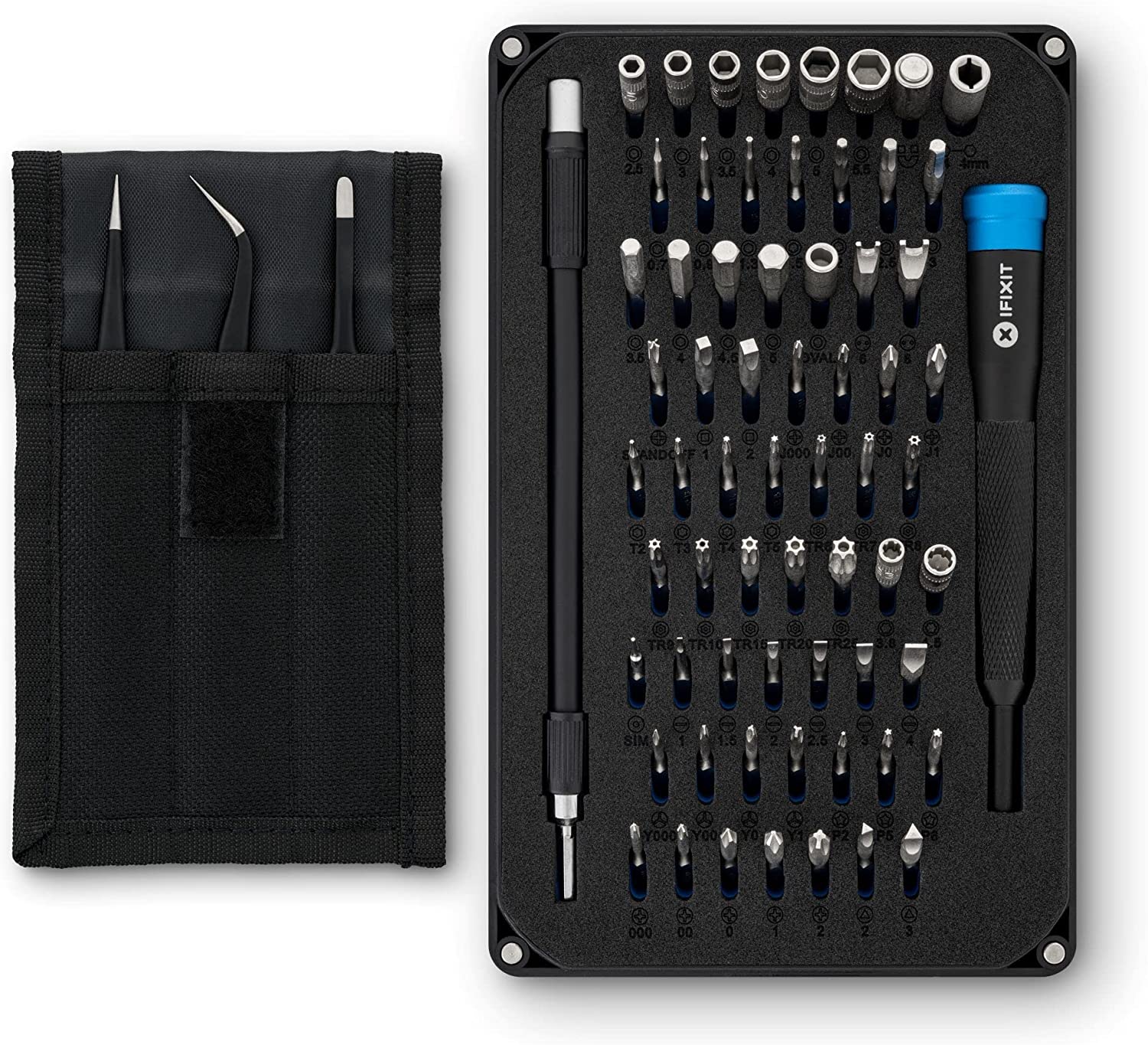

Pick up some tweezers and screwdrivers (including hex keys and torx) from a great brand.

Soldering

You will probably not use your soldering iron that often with microelectronics. I elect to spend a little bit less on my soldering iron proper and quite a lot on my actual solder. Grab something super cheap and a handful of tips.

Spend your real money on nice, leaded solder. Loctite makes some nice stuff. Be sure to wash your hands after handling!

Pick up a spool holder. You could use spool for leaded, one for unleaded.

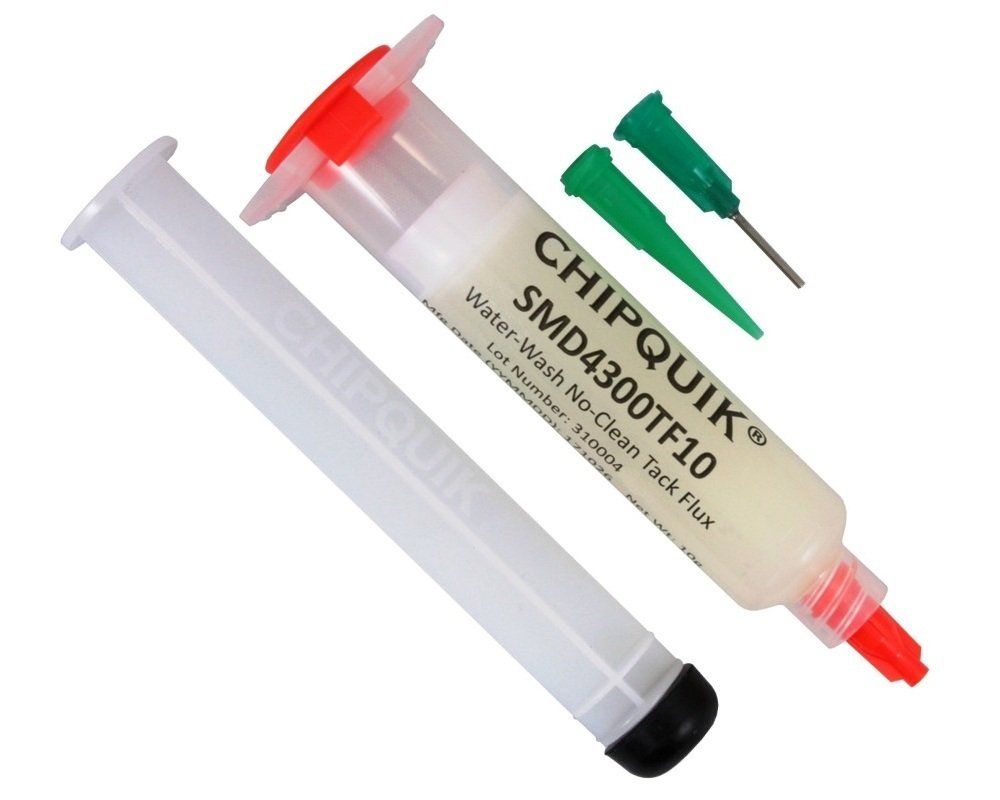

Grab some nice flux!

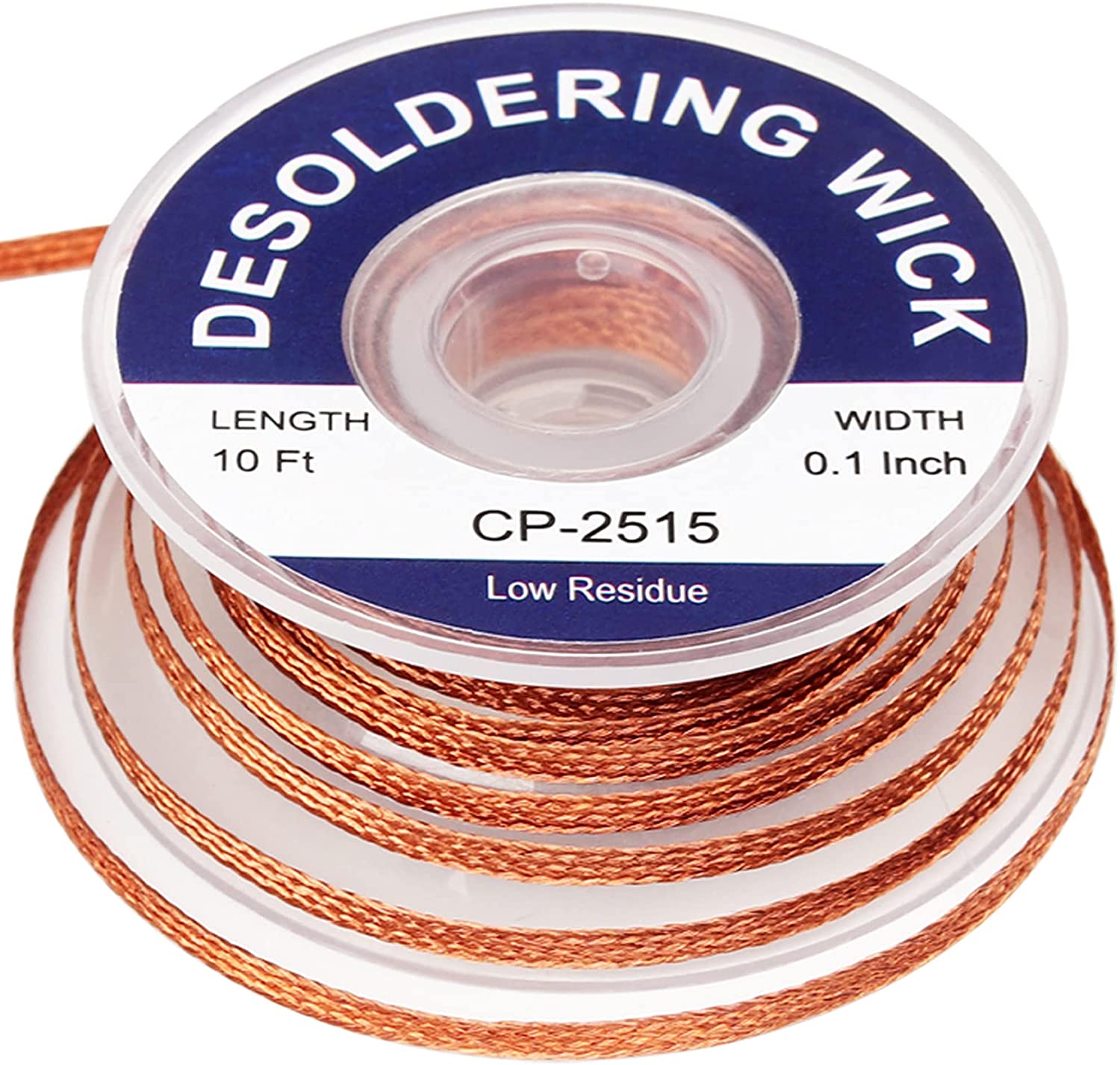

And some solder wick to clean up pads after desoldering.

Also spend the couple bucks on tip tinner and a brass sponge to stretch the lifespan of your iron's tips.

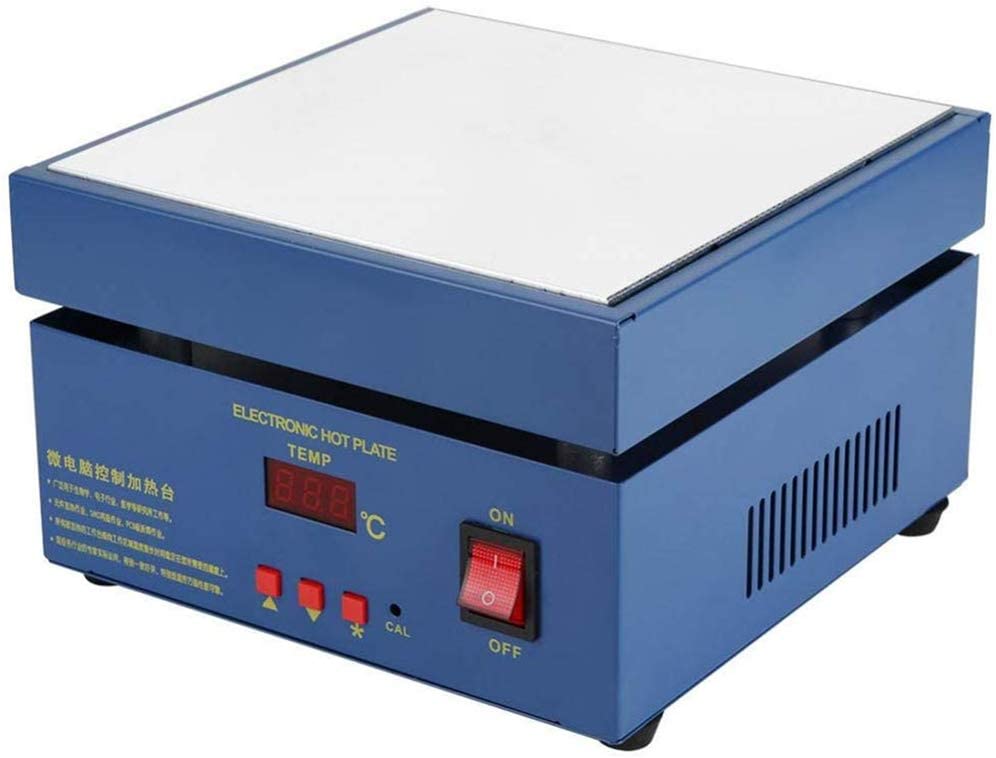

Get a hot air reflow station and a hotplate.

Also pick up a decent microscope with a light. I use this one but you could probably get away with a USB microscope.

Chipquik makes excellent solder paste. Be sure to keep it in a cool place when not in use. Get the little jar so that you can save excess solder paste after stenciling.

Grab some magnet wire and solid core tinned wire for fixing PCB errors. The enamel wire can have its plastic coating burnt off with a blob of solder but is insulated elsewhere. Louis Rossmann uses magnet wire for many of his repairs.

Be sure to use Kapton tape. It is very thermally stable and holds great. You will find a million uses for it.

Finally, pick up an Omnivise for holding boards when soldering.

You're on the way to being a true blue embedded engineer. I use many of these tools on a daily basis and hope you find use from them too! If you feel that I've missed something don't hesitate to reach out on our Discord!